Industry news

Introduction of Tungsten Carbide Cutting Tool

Carbide cutting tool machined parts can obtain the required dimensional accuracy and surface quality, is the most basic processing method in the machinery manufacturing industry.

Cutting processing refers to the method of using tungsten steel cutting tools (carbide cutting tools) to remove excess material from the machined parts. Cutting processing with tungsten carbide cutting tools occupies an important position in the national economy.

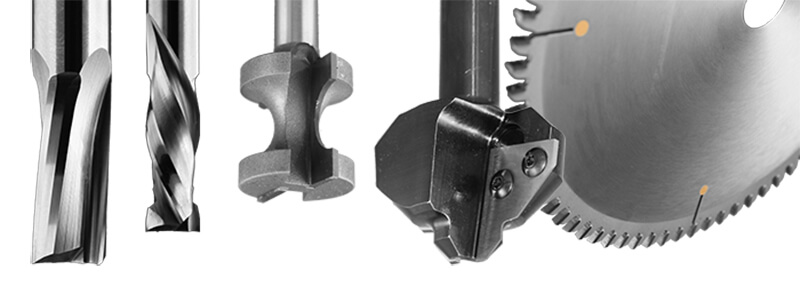

Carbide cutting tools are of various types and have different classification methods. According to the processing mode class: divided into turning tools, drills, boring tools, reamers, broaches, milling cutters, threading tools, gear cutting tools, CNC cutting tools and so on. From single-edged to multi-blade, from simple to complex.

Different types of tungsten steel cutting tools have different numbers of cutting surfaces and cutting edges. However, the most basic unit of tungsten steel cutting tool is a cutting edge which is intersected by two cutting surfaces, referred to as two surfaces and one edge. Any complex tungsten steel cutting tool can be divided into a basic unit for analysis.

In the metal cutting process, the cutting part of the carbide cutting tool directly completes the cutting work. The advantages and disadvantages of carbide cutting tool material performance directly affect the quality of the tool. Cutting productivity and tool durability of the high bottom, parts machining accuracy and surface quality, etc., to a large extent depends on whether the choice of carbide cutting tool material is reasonable.

In the process of metal cutting, carbide cutting tools not only withstand a large cutting force and high temperature, but also withstand impact load and mechanical friction. Therefore, the carbide cutting tool material must have high hardness, high wear resistance, sufficient strength and toughness, as well as good high-temperature heat resistance, chemical stability and thermal conductivity and other aspects of performance.

Cemented carbide cutting tool cutting process refers to the process of cutting excess metal layer from the workpiece by the carbide cutting tool through the cutting movement, and the formation of chips and the process of the process of the machined surface, in the process of the carbide cutting tool to produce deformation, the formation of chips, cutting force, cutting heat and cutting temperature, cutting tool wear and many other phenomena.

Carbide cutting tools are tools made from hard alloy materials, typically composed of tungsten carbide particles (a hard compound of tungsten and carbon) held together by a metallic binder, often cobalt. The combination of tungsten carbide and the binding metal creates a tool with exceptional hardness, wear resistance, and strength, making it ideal for cutting, milling, drilling, and shaping various materials.

Carbide cutting tools are widely used in industries such as metalworking, woodworking, construction, and manufacturing due to their ability to withstand high temperatures and maintain their cutting edges for extended periods. They are available in various forms, including inserts for milling cutters, drills, reamers, turning tools, and other cutting implements.

These cutting tools are particularly advantageous in demanding machining applications, where conventional high-speed steel tools would wear down quickly or become inefficient. The hardness and durability of carbide cutting tools enable them to cut through tough materials such as metals, alloys, composites, and even some hardened steels with precision and efficiency.

Overall, carbide cutting tools are essential components in modern machining processes, contributing to increased productivity, cost-effectiveness, and the ability to achieve complex shapes and high-quality finishes in a wide range of materials.

Hunan Jetvision Industrial Co.Ltd is a professional supplier and manufacturer which offer kinds of tungsten carbide products, such as cemented carbide cutting tools, carbide insert, carbide tips, carbide nozzle, carbide valve seat, tungsten carbide blade, carbide rod,carbide dies, carbide tube, carbide sheet, carbide ball, carbide seal rings, carbide vale seat,etc. high quality and low price

Keyword: cemented carbide cutting tools supplier, tungsten carbide cutting tool manufacturer, buy cheap carbide cutting, cemented carbide blade made in China, wholesale tungsten carbide cutting tool, carbide tips in stock, cemented carbide insert price list, carbide cutting tool manufacturer and supplier, tungsten carbide cutting price list, buy cheap cemented carbide cutting

Prev:Introduction of Cemented Carbide Nozzle

Next:What Machines are Needed to Produce Cemented Carbide Round Rod?